MAN RG CENTRIFUGAL COMPRESSORS: EQUIPMENT& SPARE PARTS

The MAN RG compressors from R&H Supply are engineered for efficiency and versatility, featuring advanced design and manufacturing.

Key Features:

- Multi-Stage Arrangement: Up to five pinions and ten impeller stages for optimized compression.

- Intercooling Capability: Allows for intercooling after each stage, reducing power needs and enhancing efficiency.

- Flexible Process Stages: Individual process stages within a single casing are possible, contributing to more efficient operation.

- Maintenance-Free Bearings: All shafts are equipped with maintenance-free tilting pad bearings for reliable performance.

- Compact Design: The thoughtful arrangement allows for a very compact footprint.

- Versatile Gas Compression: Suitable for a wide range of gases with a high pressure ratio.

- Enhanced Impeller Design: Improved design for pinion speeds and aerodynamics ensures top efficiency levels.

- In-House Gear Manufacturing: Gears are manufactured in-house, guaranteeing quality and precision.

Capacity and Specifications:

- Varied Sizes for Different Needs: Available in different sizes to suit various requirements.

- High Flow Rates: Capable of handling flow rates up to 600,000 m³/h.

- High Discharge Pressure: Offers up to 250 bara discharge pressure.

Benefits:

- In-House Manufacturing: Ensures quality and reliability in gear production.

- Advanced Cooling Options: Intercooling after each stage enhances performance and energy efficiency.

- Customizable Process Stages: The ability to configure individual stages within one casing for operational efficiency.

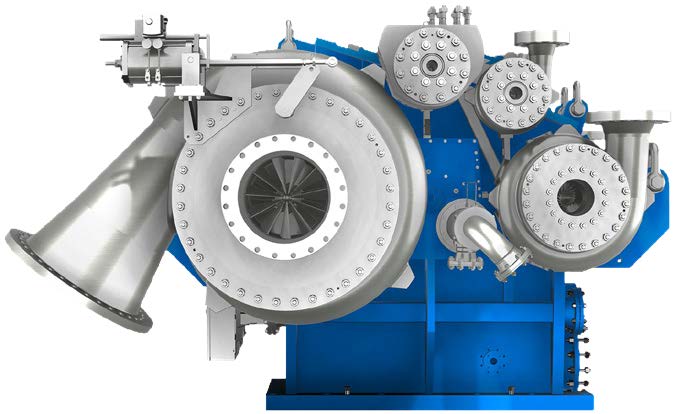

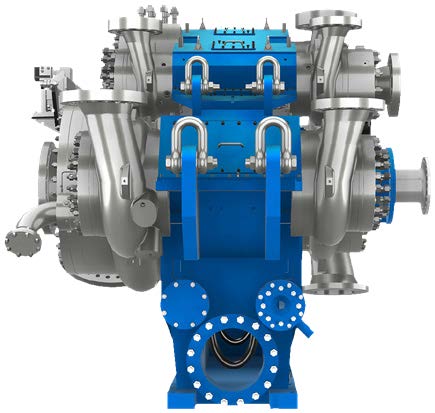

MAN RG

High efficiency multi-shaft centrifugal compressors

Dimensions

| Type* | RG25 | RG40 | RG45 | RG50 | RG56 | RG80 | RG100 | RG140 | RG160 |

|---|---|---|---|---|---|---|---|---|---|

| L (mm) | 2,700 | 3,000 | 3,400 | 3,700 | 4,000 | 4,500 | 5,500 | — | — |

| H (mm) | 3,600 | 3,600 | 3,600 | 3,600 | 3,600 | 3,600 | 3,600 | >3,600 | >7,000 |

| W (mm) | 2,000 | 2,500 | 3,000 | 3,300 | 3,500 | 4,000 | 5,000 | 7,000 | >7,000 |

| Weight (t) | 15 | 30 | 40 | 45 | 50 | >60 | >80 | >100 | >140 |

*Dimensions related to core unit

Output

| Model | Flow in Am³/h | Power in MW |

|---|---|---|

| RG25 | 10000 | 4 |

| RG40 | 25000 | 15 |

| RG45 | 30000 | 18 |

| RG50 | 40000 | 20 |

| RG56 | 50000 | 20 |

| RG80 | 100000 | 20 |

| RG100 | 200000 | 35 |

| RG140 | 350000 | 50 |

| RG160 | 600000 | 75 |

Compressor features

Key Specifications

- Driver Options: Electric motor, steam turbine, or gas turbine.

- Minimum Suction Pressure: 0.03 bara, in compliance with API standards.

- Discharge Pressure: Maximum of 250 bara.

- Flow Rate: Up to 600,000 m³/h.

- Power Range: Capable of up to 75 MW.

- Efficiency: Over 88% overall efficiency achievable.

- Pinions and Impellers: Up to 5 pinions and 10 impellers.

Modular Configuration

- Versatile Applications: Ideal for air, fuel gas booster, CO2 applications, and custom-manufactured high-pressure compressors.

- Standardized Preassembled Components: Ensures performance, reliability, and shorter delivery times.

- Customization Options: Individual pinion speeds from 3,000 – 50,000 rpm and impeller sizes from 90 to 1,800 mm. Discharge temperatures up to 450 °C.

Multistage Design

- API Compliant: Fully complies with API requirements, with intercooling between each stage.

- Multiple Services Capability: Each unit can offer multiple services due to its versatile design.

Applications

- Industrial gases, CCUS, heat pumps, hydrogen (H2), high-temperature compression.

- Oil & gas, refineries, chemicals & petrochemicals, fertilizer industry.

- Iron & steel, mining, power generation.

Flexible Control System

- Anti-Surge System: For multiple stage groups.

- Performance Control: Ensuring optimal operation.

- Inlet Guide Vanes: Available at the first or several compressor stages.

- Variable Speed Control: Along with suction throttling options or combinations for flexible operation.